Supply-chain issues and increases in the cost of materials have played havoc with self-storage construction projects, often causing delays and big hits to the wallet. A design-build approach can help a developer or owner manage these challenges. Find out how.

Though every self-storage owner and builder wants their construction project to come in on time and within budget, meeting these targets is more important than ever in today’s inflationary environment. Since the pandemic, the materials cost escalation and supply-chain delays have had an adverse effect on development, leaving many projects dead in the water. However, there’s a solution: Get your general contractor (GC) on board early, so they can participate as a consultant in your design planning.

This is what happens in a design-build (DB) approach to self-storage construction. If you aren’t familiar with this method, read on to understand its many advantages.

Old- vs. New-World Order

Until recently, the design-bid-build (DBB) approach to construction has been largely accepted as the most cost-effective way for self-storage developers to ensure they receive the best pricing. In this model, the owner/builder first engages an architect, who brings on board civil and structural engineers as well as mechanical, electrical and plumbing consultants.

From there, the team presses forward, from schematics and design to construction drawings. Once these are complete, they’re sent to three to five GCs for bids. The bids are leveled and a GC is chosen, often the one with the lowest price.

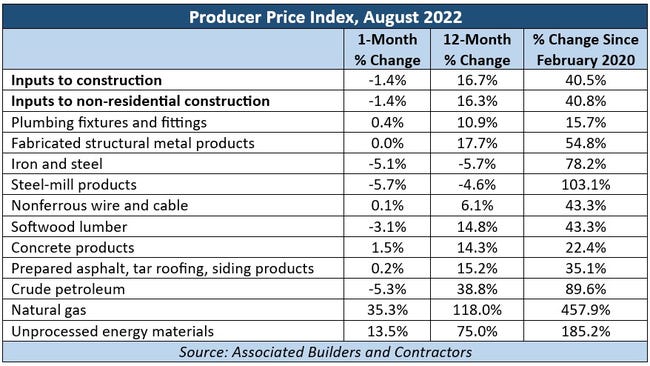

This where developers can run into problems today. They can no longer rely on historical data to get them through underwriting, as the information is no longer relevant. This results in projects coming in over budget, which then requires them to pay the design team a second time to go back and find a way to make the project pencil out again. The following table offers a good illustration of the pricing volatility that has occurred in the market.

In addition to material-price escalation, the construction industry has been hit hard by supply-chain crises and the availability of necessary materials. This has become such a pressing issue that, in some cases, the lead time can exceed the total duration of the construction schedule, leaving projects idle. This costs owners and builders more, as interest carry ticks away without lease-up revenue kicking in.

The most expensive component of any self-storage development isn’t the architect, permitting or even the consultant fees. It’s the cost of hard construction. And yet, more often than not, the GC is the last person to see the drawings. This is why, instead of taking a DBB approach, many owners and builders are exploring a DB or construction-manager-at-risk (CMR) delivery method, both of which bring the GC on board early in the design process to work alongside the rest of the team.

This allows everyone to work together toward common goals. Involving the GC from day one provides clear visibility of up-to-date pricing. It also allows the team to identify long lead items that have the potential to lengthen the schedule.

Working with a GC to establish a baseline budget that’s updated at each design phase enables the development team to adjust as necessary before plans are complete and approved by the city. As the drawings progress, the GC provides revised costs, and everyone involved is aware of any changes. They can then begin to determine if the project is heading in the desired direction, offer alternatives as needed, and make suggestions to ensure it stays aligned with goals. This process also allows the GC to identify materials with long lead times and procure them before construction begins.

Comparing Methods

Let’s compare how these self-storage construction methods differ using a project example. The average 100,000-square-foot, class-A self-storage facility takes roughly 12 months to build. As of May, electrical switchgears had a lead time of approximately 56 weeks. In a DBB approach, that item couldn’t be ordered until a GC was chosen and a contract signed. The owner would have to delay the start of the project by four weeks to ensure the switchgear arrives on site in accordance with the construction schedule, or move forward and risk idle time waiting for the part. Both cost time and money.

Alternatively, if the GC is involved from the beginning, work can be done upfront with the design team and public-utility company to design and approve an electrical-service plan. This allows the team to procure an early submittal and order the switchgear before the project ever gets a building permit.

The below graphs, taken from the Design-Build Institute of America’s “Design-Build Data Sourcebook,” illustrate the differences between the DBB, CMR and DB approaches. Across the board, self-storage owners typically see a lower percentage of cost growth and schedule lengthening with DB, all while benefiting from a faster delivery time when the GC is brought on board at the beginning of the development cycle.

An Advantageous Path

Over the past five years, self-storage owners and builders have seen unprecedented price escalation in materials and issues with item availability, making it difficult to keep projects on track. While there’s always the option to throw more money at these problems, perhaps a better solution is to reconsider project-delivery methods.

The data shows that getting your GC involved early in the development process is to your advantage. Making consistent updates throughout the design phase allows the team to offer solutions as needed. Completing a self-storage construction project on time and within budget is still possible. It just might look a little different than in the past.

Shane Elias-Calles is business-development leader for Consolidated Contracting, a general contracting firm that specializes in self-storage, senior living, affordable housing, health care and retail construction. With more than five years of self-storage construction and development experience, he holds bachelor’s and master’s degrees from Vanguard University of Southern California. To reach him, call 949.324.3424; email [email protected].

About the Author(s)

You May Also Like