First-time self-storage developer Rob Taylor considered his rural communitys storage needs before embarking on what would become a seven-building self-storage complex.

August 21, 2013

By Kevin Hutchings

Self-storage facilities became part of the landscape 30 years ago and have evolved to meet the demands of consumers and their varying needs. In recent years, industry trends have included climate-controlled units, condo-type storage thats sold rather than rented, construction of larger units for boats and RVs, and the slow, steady expansion of self-storage to rural areas.

The last of these trends proved to be a successful business opportunity for Rob Taylor of Taylor Made Storage, a seven-building self-storage center near the Kansas State University campus on the outskirts of Manhattan, Kan. Self-storage operators achieve success by developing facilities with the right location and unit mix, and finding an untapped niche in their market. Taylor honored these principles when developing his project.

Self-storage was a new venture for Taylor, who owns an adjacent trapshooting park and other businesses. Only 10 acres of the 15-acre park are devoted to the trapshooting range, leaving 5 acres on which self-storage seemed like a good investment, Taylor said.

The Contractor and Building Specs

Taylor chose DJ Carpenter Building Systems, a Butler Builder based in Manhattan, Kan., to help him make his dream a reality. Company owner Dave Carpenter noted the growth of self-storage in rural areas. Weve noticed a pattern that many of the smaller towns around Manhattantowns the size of 2,000 or 2,500 [people]have self-storage as well, he said. Each town will typically have one building with maybe 25 units to serve the needs of their community.

As consumer preferences for self-storage evolve, so must building specifications. For example, many metal-building manufacturers offer a wide range of options including climate control, multi-story buildings, wind-rated doors, and extensive exterior finishes including metal, concrete block, tilt-up or brick to create an attractive appearance and meet local building and energy codes.

Taylor and Carpenter ultimately built seven buildings using the Butler Manufacturing Self-Storage System, an integrated package that includes the MR-24 Roof System, Butlerib II Wall System, wind-rated doors and interior subsystems. Though self-storage lenders normally prefer the better return on investment from larger, multi-building projects, Taylor opted to develop his center in conservative, building-by-building phases.

Thats how Taylor Made Storage became what it is, Carpenter said. Rob Taylors philosophy was build one, fill it up, get it paid for, and then build another one. When a building reached 92 percent capacity, Taylor would construct another free-standing structure. Today the complex features 143 units, all with outside access doors.

Adapting to Customer Demand

Through this strategic building process, Taylor learned what would work best at his center, and some of his early presumptions changed. His first building was 100 by 35 feet, divided into eight 10-by-20-foot units, eight 10-by-15-foot units and 14 5-by-10-foot units. He felt this would give him the typical mix of what rents elsewhere in the city. However, the smallest units, which are usually in high demand near the university, didnt rent quickly. He finally filled them by offering a discount for six-month pre-pays.

Taylors second building was the same size, but the unit mix included the larger, deeper units in demand by small businesses, homes in rural towns, and farmsteads that lack basements or other onsite storage space. Two nearby recreational lakes also created demand for larger units used to store boats.

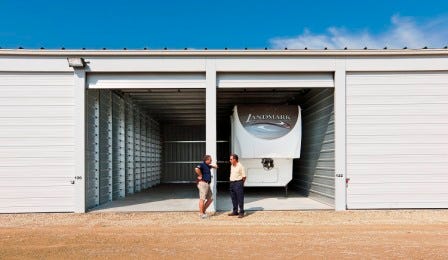

Taylor's most recent project was inspired by Kansas State fans who wanted a secure space to park their RVs rather than drive them back and forth during weekend sporting events. Some of these high-end RVs can cost from a couple hundred thousand dollars to a million dollars, he said. We had some folks calling to inquire about having fully enclosed [units]. In the past, this market historically had only open-sided, canopy-type [units].

Taylors new generation of high-bay buildings are divided into a dozen 12-by-50-foot units with 14-foot-high doors. Customers can subscribe to a 30-amp electrical service for a flat fee to keep their RV batteries charged. By avoiding 50-amp service to the units, Taylor prevents tenants from running their energy-gobbling air-conditioning on facility power.

A Vibrant Industry

While unit size and amenities may dictated by consumer demand in a given area, building quality is always important. Tenants need to know their unit is built to last, so their property is protected from the elements and can be easily accessed. Ironically, that attribute kept the self-storage industry alive and well, even during the most recent economic turndown.

We noticed that when the economy gets difficult, people want to hang on to their stuff, Carpenter noted. They dont go to their self-storage unit and sell off all of their stuff. They put more stuff in there.

As the economy continues to rebound, industry leaders predict self-storage, in all forms, will remain a vibrant industry and continue to serve the growing needs of urban and rural consumers.

Kevin Hutchings is the training manager for Kansas City, Mo.-based Butler Manufacturing, which provides a combination of design-build construction solutions and building technology to the non-residential market. In his position for 15 years, Hutchings is responsible for the company's product-builder management and sales training. Butler is a division of BlueScope Buildings North America Inc. For more information, visit www.butlermfg.com .

You May Also Like